So, a few weeks got away from me. The day job was busier than normal, a few more personal obligations than normal and suddenly I find myself not in the shop. These things happen when you are a part time woodworker. Occasionally my non-woodworking life takes over. The important part is to try to limit the amount everything else takes (where appropriate, things will happen).

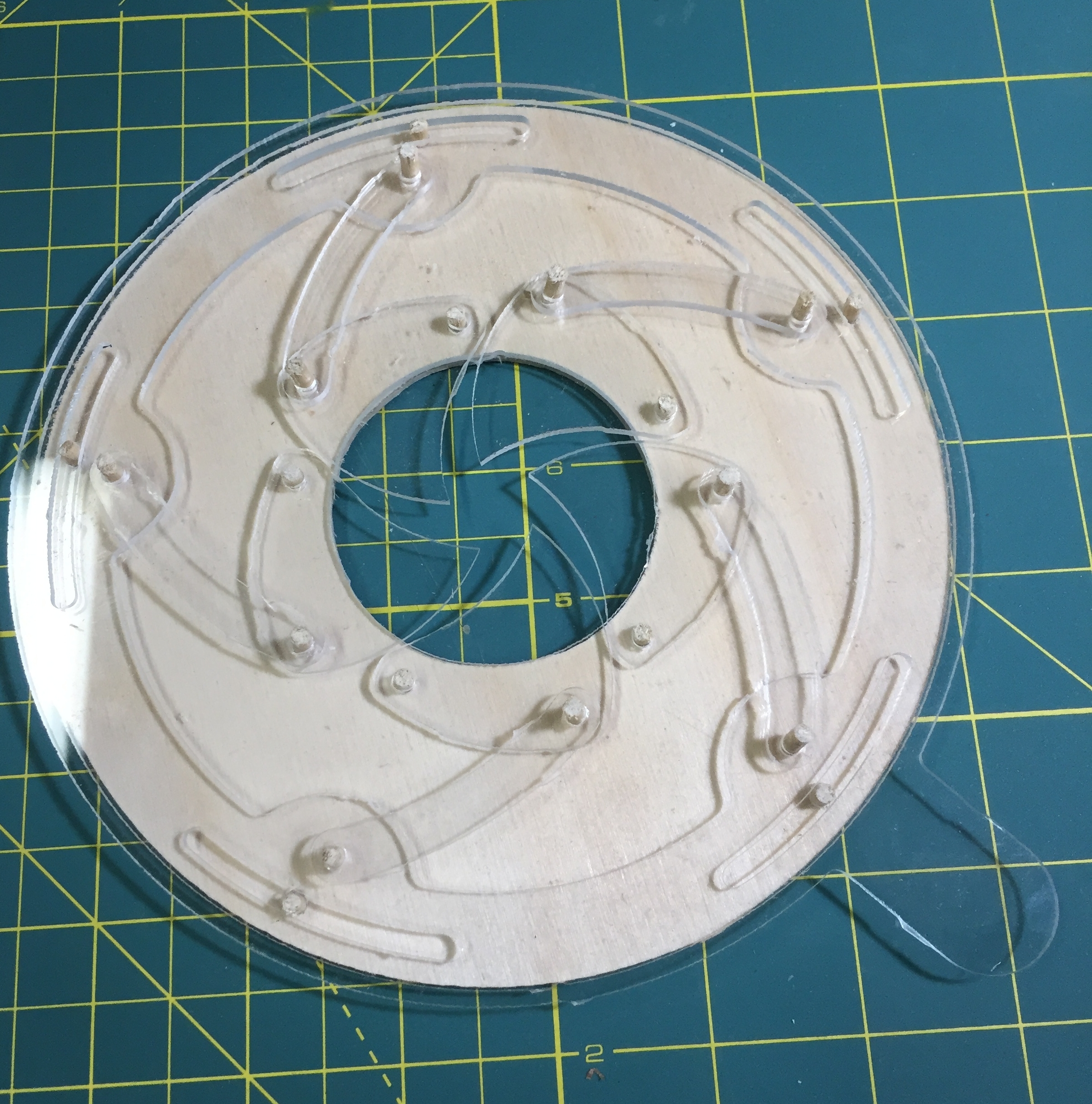

I didn’t get a ton of time back in the shop, but I got some! I have several things to do so I just had a to pick a place to dive in. I chose a rebuild of the iris drawer which is part of the engagement box commission (more on it’s hold up in a bit). The iris was beginning to bind up in the oppressive humidity we’ve had lately in NE Pennsylvania recently and wasn’t working smoothly. Initially, I wanted to get this done and just glued the box together, top and all. Which, of course, means I had no way to fix the mechanism. So, I decided to make a new one which had a removable top. The main build was quick, just four side pieces. I had the plans for the CNC so cutting new iris parts was simple. The change I made was to add corner blocks with threaded inserts which would hold bolts that come in through the top. That just took a bit of measuring but was pretty simple. I also didn’t extend the dowels of the iris up through the top so it looks much cleaner. Lastly, the parts are made from cherry ply to match the rest of the box (I didn’t have that initially). My retaining ring did break and I had to make a new one, but that was no big deal. Bead moulding is on the front, recess for the latch is on the bottom, oil is applied. Now I wait a few days before topcoating.

I had a bit more time to turn my attention back to the lid of the engagement box. I had wanted to make some hearts that would cover the keyholes but could swivel aside. This just took a bit of time in v-carve to draw the design then a mere minute or two to cut on the CNC. I have to clean them up but they look nice and will add a bit more visual flair to the lid. I’m thinking of trying a relief carving for the top as well.

The hold up on the box has been the laser engraving. I want to use a nearby Fab Lab (makerspace) so I get to learn the equipment and can continue to use it in the future. Back in June they were moving to a new space and were supposed to be done my mid July. Well, that turned into early September with delays and problems. Once they were running again I called to grab some time only to find out the laser wasn’t venting correctly and a fix could take another couple of weeks. So, here I am in Mid Oct hoping I can get the last pieces done soon. Hey, the delay gave me time to make the new iris drawer so it was kinda good, I guess?

About 2 weeks ago I also completed my article for an upcoming issue of The Metagrobologist Magazine. The publisher loved the article and is working on getting it in place. Very excited to see that move forward. I loved writing the article and it’d be great to do more. I can’t believe I’m going to be published. That’s a direction I didn’t originally see my life going. Some of that old college education is coming in handy.

Light week for me, but at least a few things happened!

Until next week, stay dusty.