2019 is moving along full steam here in the Cryptic shop. I know I’m a day late on my posting but Sunday was pretty busy and I had to finish a post for my Lightly Reasoned blog (worth having a look if you’re into critical thinking concepts and some oddball humor). Winter is also starting to assert itself a bit here in the Northeast US. I have to start warming up the shop a bit before I get to work. Luckily it hasn’t gotten too cold and after about a half hour the shop is t-shirt comfortable.

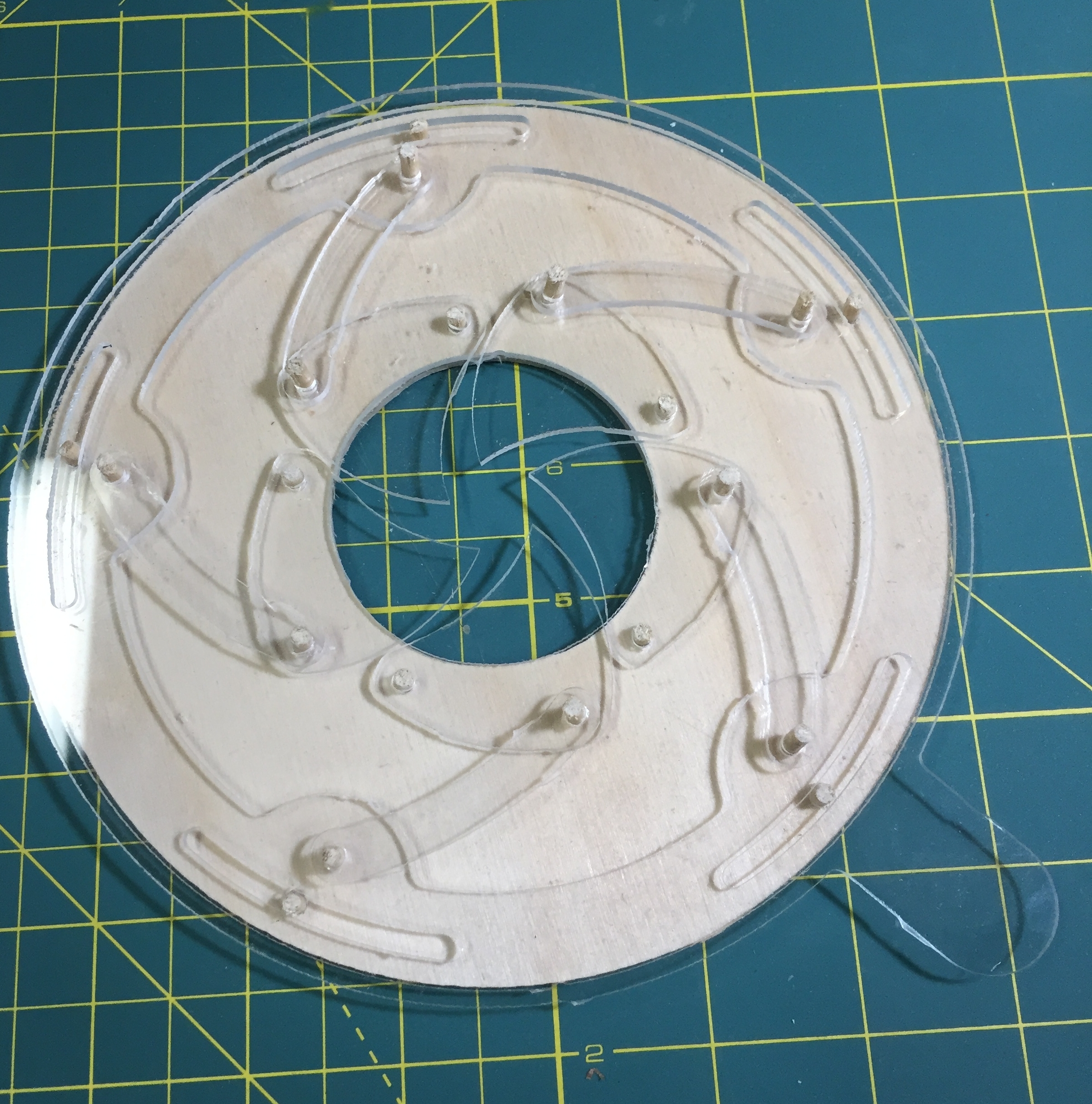

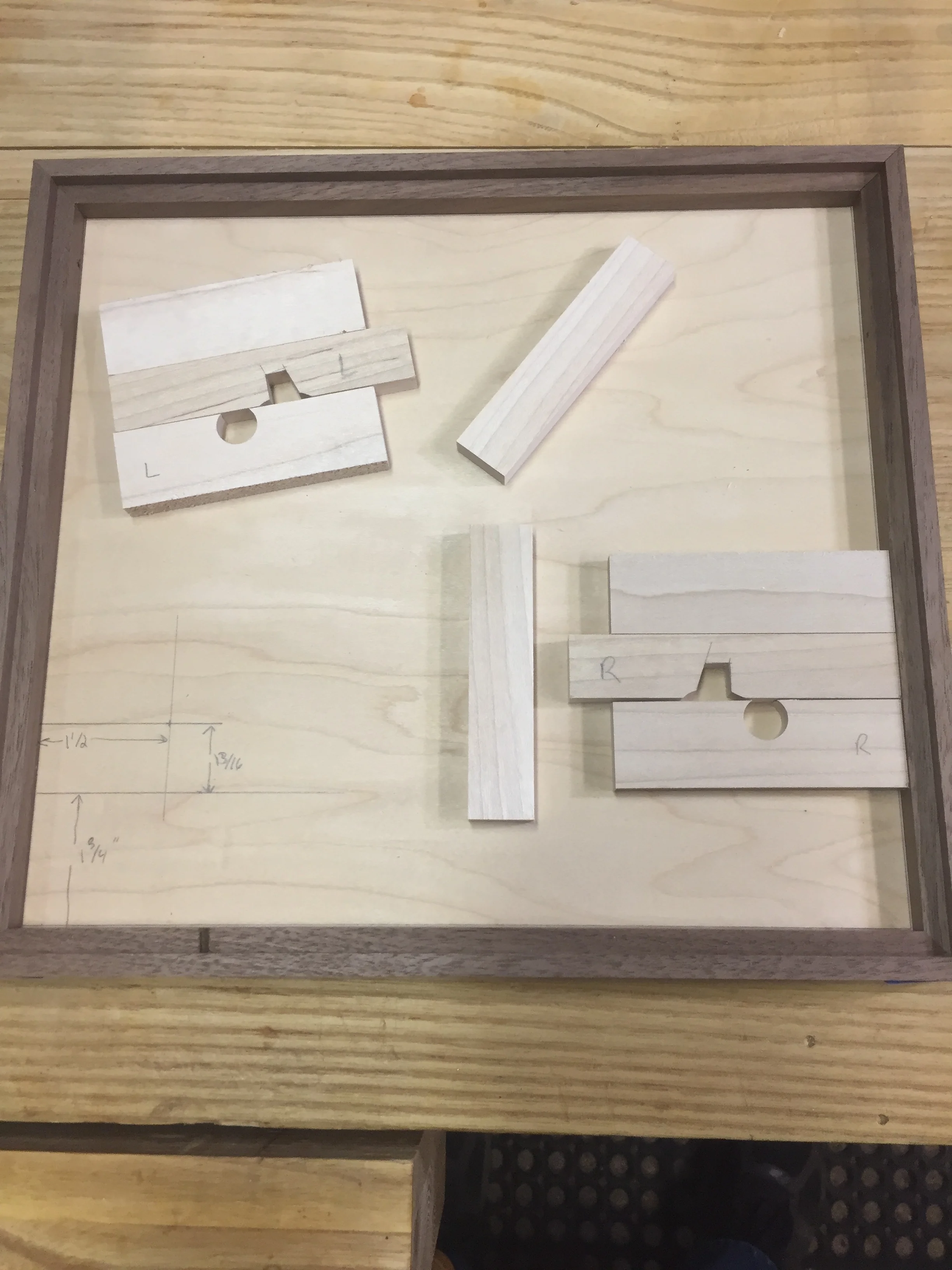

Last week was a little light on the work but yet oh so satisfying. I wrapped up the engagement box. Yep, that’s right, it’s done. I assembled the lid the previous weekend and fit it to the box. All it needed then was a few coats of wiping poly as a topcoat which I took care of during the week. After that I smoothed everything with some 320 paper so it’s silky smooth now. I cut the brass hinge pins to size, sanding the final bit and attached the lid. Same with the side compartment hinges, cut and sanded to size then glued them in with a bit of CA glue. Lastly was putting on the brass caps for the sliding side puzzles with some blue Loctite - the blue is removable with normal hand tools. Wouldn’t you know it though, I ran out of Loctite and needed a quick store run. Be careful with Loctite, it can leak out and stick a part to the box - I have a few I’m making sure are loose enough to move and don’t stick. Since they are removable I can make small adjustments where needed.

I did some showing off of the finished box to may parents. They enjoyed getting a chance to see it’s secrets and mechanisms. Then I had to try and fix their audible account which meant hanging out on a phone with support. Hey, that’s what we do for our family. I learned a lot of my woodworking with my dad in his garage shop.

I got some rearranging and cleaning done in the shop too. Moved the sander and band saw to more accessible spots. Lathe is fully open and ready for use plus the cart it’s on is right behind me at the bench giving me more drawers to use. Its a safer place for my finer marking and measuring tools. I also talked with my neighbor, an electrician, about doing some wiring in the shop to give me more receptacles which I could really use.

As I said, bit of a light week but boy does it feel good to have the full engagement box done. I’ll spend the next week making any needed adjustments, taking pictures and shooting some video. Then, it’ll make it’s journey to Australia.

Coming up? I have a sign to make now that I’m through my other projects. Then it’s on to new puzzle boxes. I’m already thinking through some designs and locks. I’m looking forward to digging into those.

Until next week, stay dusty!