I’ve had a fun couple of days in the shop. The weather is getting colder but the kerosene heater deals with that. The day job wasn’t quite as busy which gave me some extra time to work. Christmas is closing in so I’d better get to work on presents, but hey, I’ve got a week!

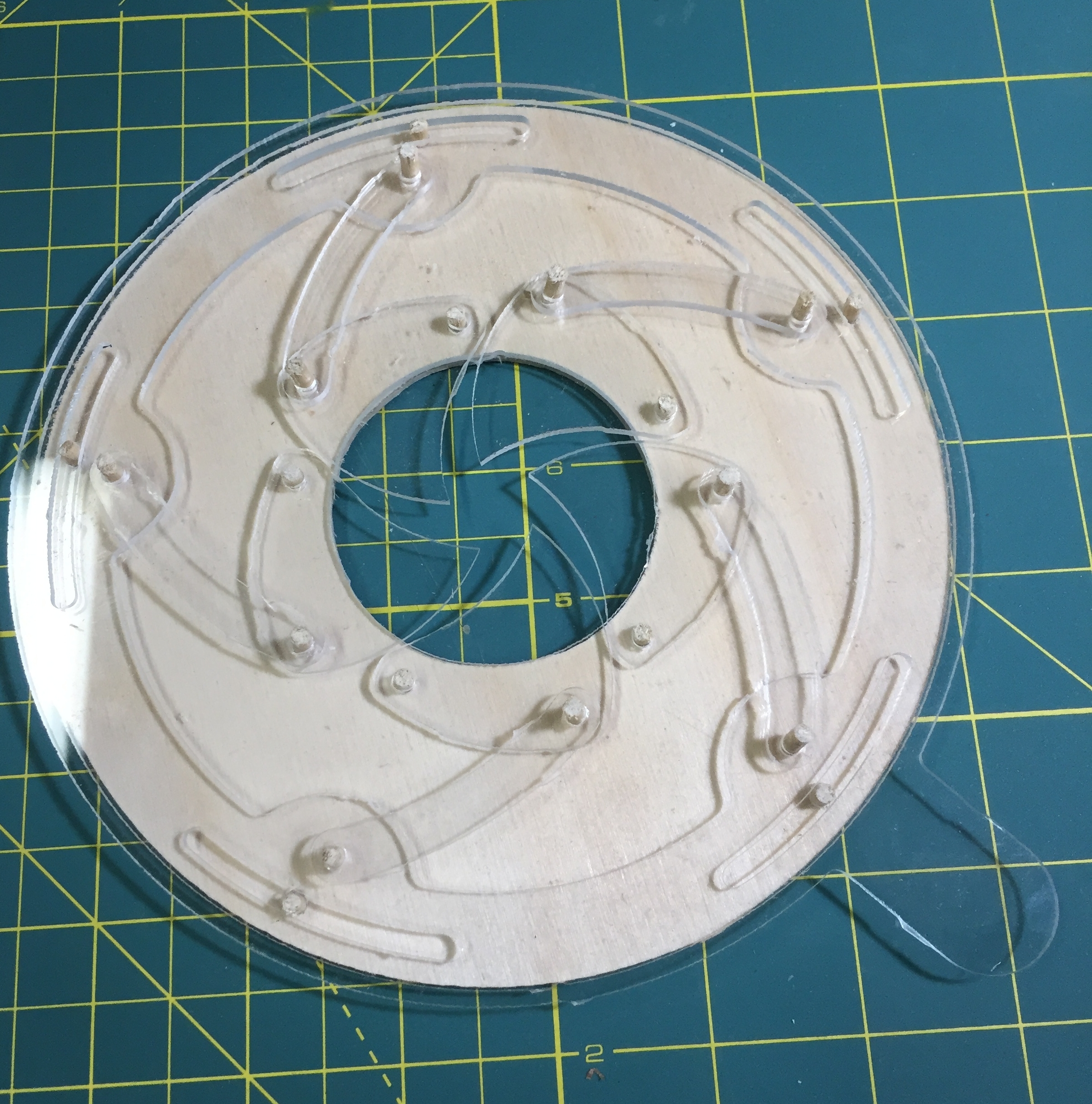

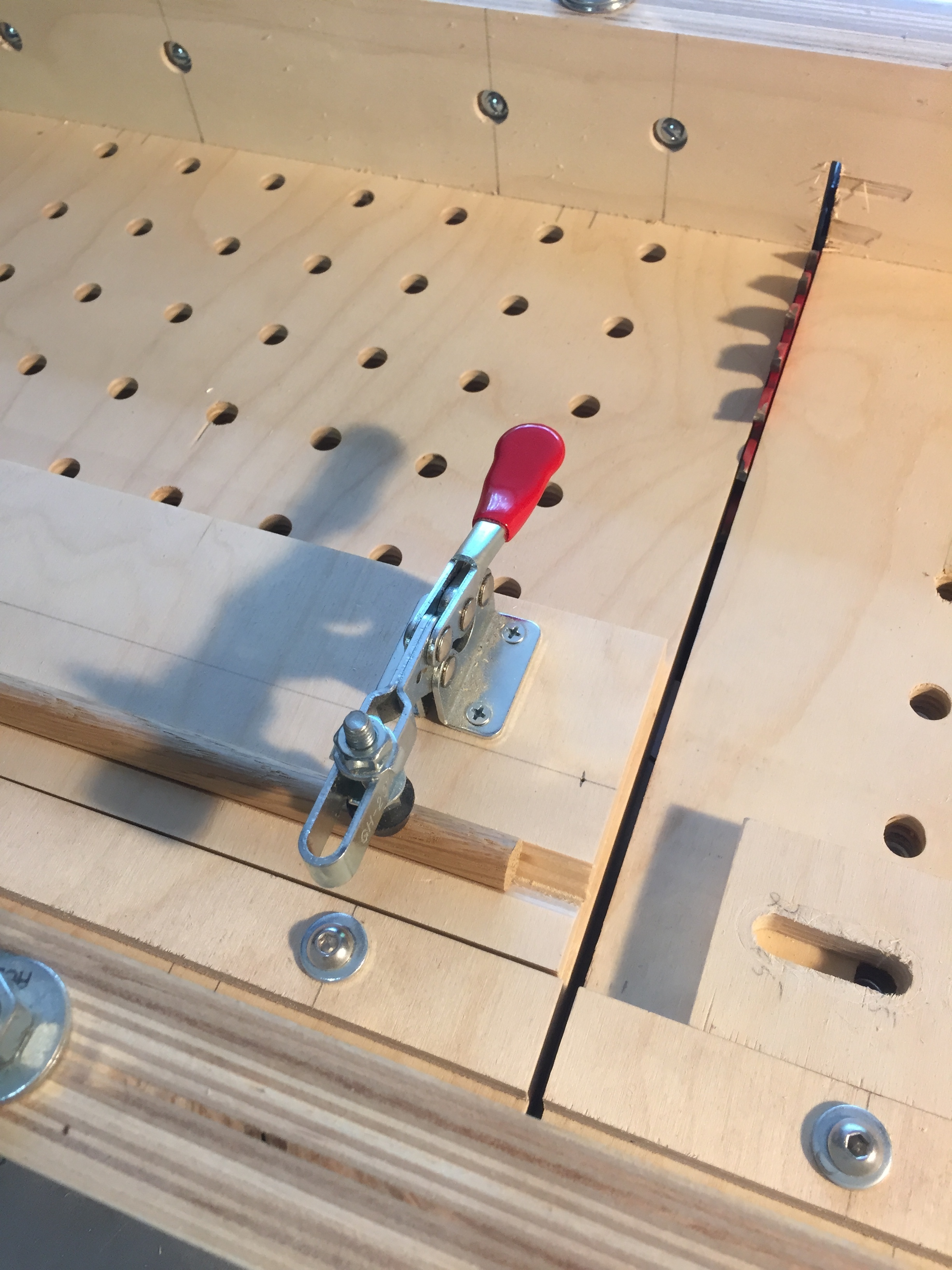

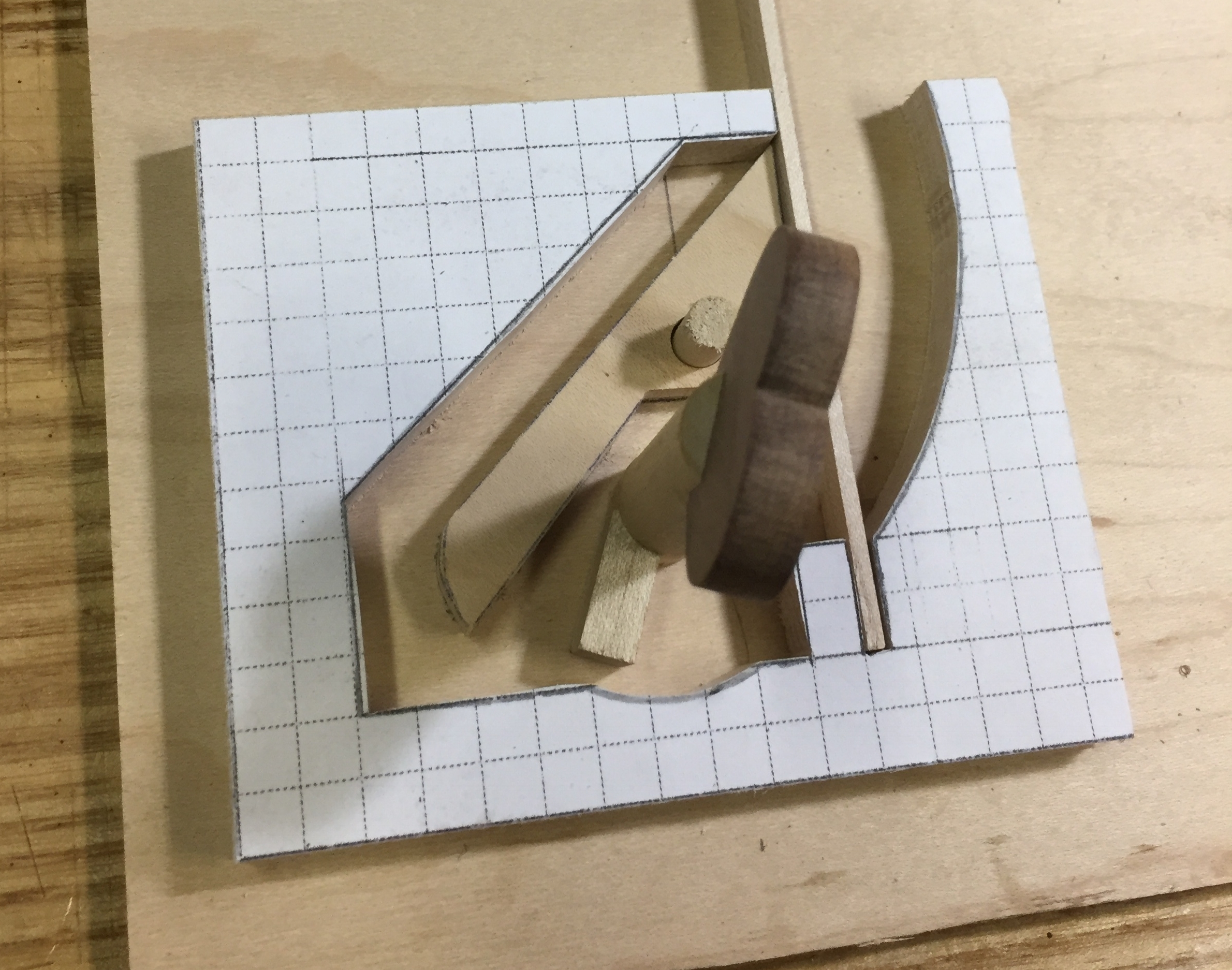

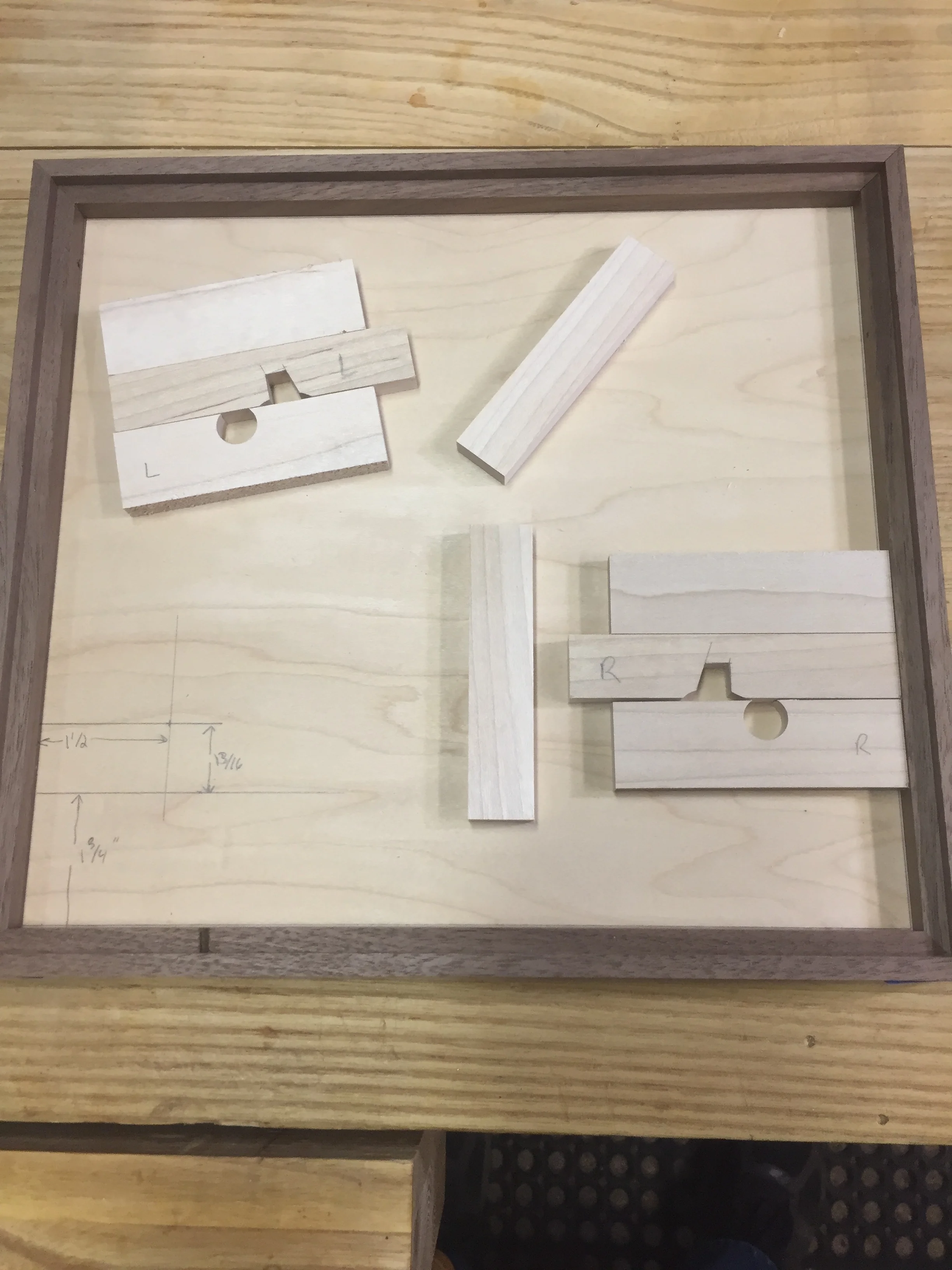

Most of my work was on the engagement box. After getting the picture transferred last week I could do some remaining work on the individual parts before assembling. I added some extra bordering and text to the bottom of the lid with the image. This was via my normal method of stencil mask, CNC carve, paint, remove mask. I cut the lock bar notches into the frame, then glued up the frame, glued in the bottom (which stays permanent) and glued down the lock components. In the picture, you can see I use a pretty standard spring lock - being simple means it also works simply and I like that. I’m attaching the top with a few screws and threaded inserts. This way, if those locks ever do have a problem someone could open and fix them. I have to get 2 more threaded inserts, I didn’t have enough on hand! What remains then is to apply some finish to the lid, put notches in the box to capture the lock bars and then drill holes for hinge pins. I can see the finish line!

I also did a quick Christmas gift job that was a CNC carved sign of a friends favorite sayings. We just layed it out in v-carve, picked nice fonts and sizes, then the usual mask, carve, paint and peel went on. Later we’ll do some light sanding, shoot on a few coats of lacquer. We wanted to do something personal and handmade. I think they make great gifts.

While I have off Monday apparently I get to go and try to find a new fireplace fan. Our went Friday and of course the shop that sells such parts isn’t open over the weekend. So, instead of shop time I get to run around, hopefully find the right fan and install it. And I was hoping to get going on making Christmas puzzles. Oh well, have to do what’s necessary, don’t we. At least without the fan on it’s still a fireplace and gets hot!

Until next week, stay dusty!