Where oh where has the week gone? I could swear it was just Monday. This happens far too often when you're an independent woodworker with a day job and a variety of other personal duties. We try our best and we find times to still make a bit of dust. And I managed to get some quality time in the shop regardless.

I have two of the new cipher wheels with the constellations on them oiled and drying. The main work here was to carve the second one, get it painted and then cleaned up. Then came time to make the dials that let you turn the inner disc. These are just two discs made from 5/8" walnut. I went simple and these and just drew them with a compass, cut them on a jig saw and sanded to my lines.

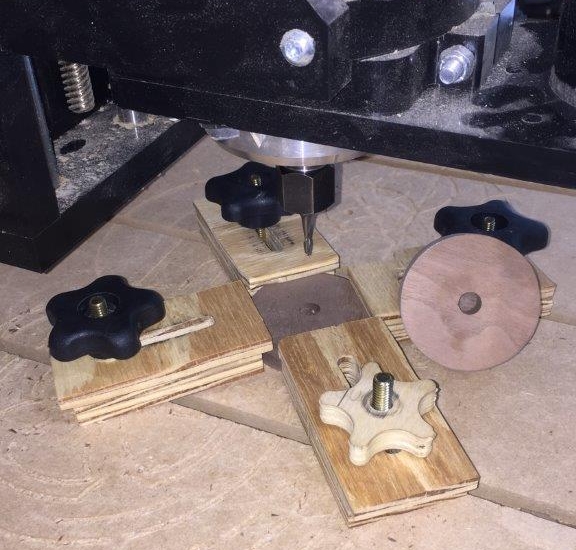

Where I added some challenge was to make a hole in the center to hold a threaded insert. I wanted a flat bottomed hole down to 1/8" from the bottom. Regular brad point drill bits would have their points go through that last 1/8". So, I mounted them in the CNC and made a quick program to cut them. I had to put in a v-bit so I could align it's point with the center of the disc (from the compass), clamp it down then switch to a 1/8" spiral and make the cut. Sure, it was probably overkill, but it worked great.

I installed the threaded inserts back at the drill press. It's helpful to have another set of hands or clamps here (I had a wife!). I cut the head off a 1/4 20 bolt so I could put it in the drill chuck them put the insert on it with a few nuts to hold it in place. From here, lower the quill and turn the chuck by hand. I repeat, turn this by hand! Pressure on the quill while turning sets the inserts totally straight. It's a great way to get the job done.

Last was a bit of sanding, glue on the dials and then put a few coats of danish oil on all the parts. Wipe them dry a bit later and now I'll let them cure a few days before top coating with some wipe on poly. They oughta look great then as I get them posted to Etsy. Oh yeah, after doing some photography. Making some new videos would be cool too.

I'm also looking for other alternatives for laser work to finish off the engagement box commission. The shop I wanted to use is closed while they move and it appears they are taking longer than expected. Made some calls and have a new person to see this week. We'll see. I had hoped to use the Fab Lab maker space so I got the experience of using the laser.

That about did it for the week. Not a lot happening, but really good to see some projects move along. Progress is progress, always good to look at it that way. Each day brings new challenges, new failures but new successes as well. It's the successes we have to keep our eyes on. Failures are just there as guides on what not to do.

Until next week, stay dusty!